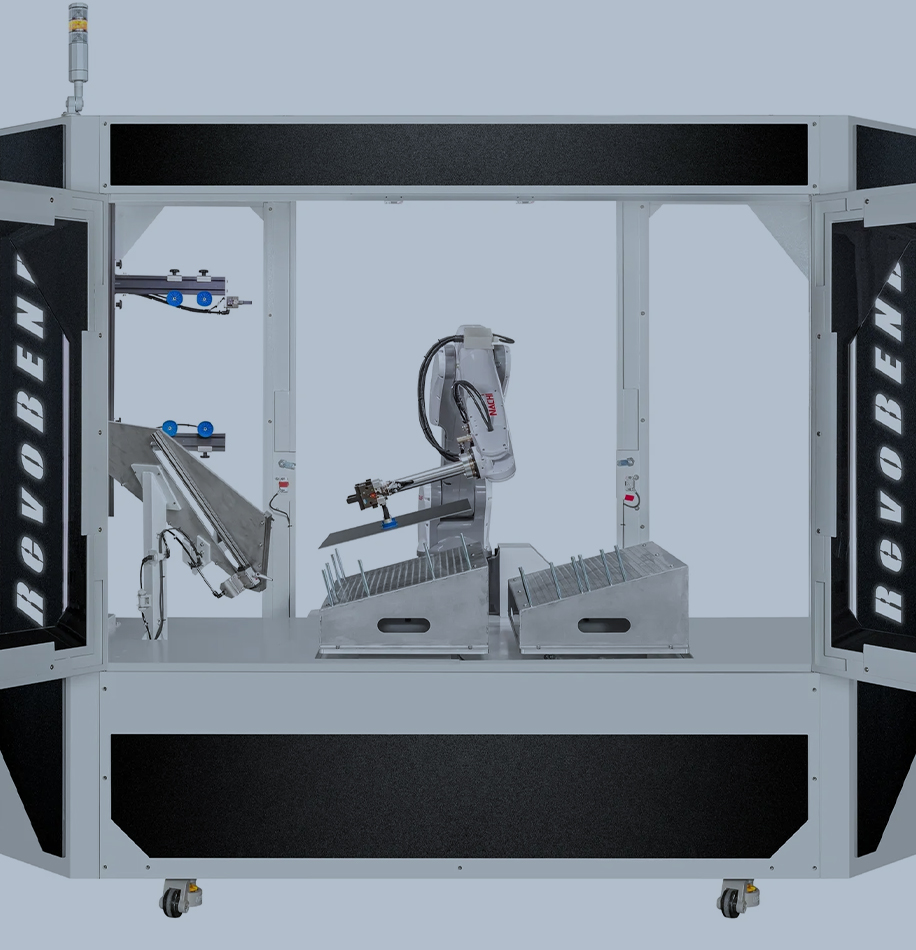

Revobend: robotic cells for press brakes!

Revosolution embodies robotics expertise combined with decades of experience in industrial bending applications. The brand is based on advanced, proven technology, designed to meet the most demanding requirements of the manufacturing sector.

Revosolution offers a series of three models of robotized bending cells, the Revobend series. Every component of Revosolution’s robotic cells is carefully selected and integrated to ensure optimum performance.

The result is a product that stands out for its reliability, precision and robustness. Our bending cells are built to last, and to deliver consistent results, day after day.

Automation and Industry 4.0

In the manufacturing industry, the pressure to improve productivity, reduce costs and maintain high quality is constant. Companies face increasing international competition, which drives them to adopt innovative technologies to stay competitive. Automation has become a key lever in this race for efficiency.

The importance of automation is also growing in a context of increasing product personalization. Consumers are demanding tailor-made solutions, and companies need to adapt their production lines to meet this demand without sacrificing profitability. Robotic cells, such as those for press brakes, enable this flexibility while maintaining high production levels.

In short, automation is no longer a luxury for manufacturing companies, but a necessity to meet modern challenges. It’s important to increase efficiency, reduce costs, improve safety, and remain competitive in the global marketplace.

One brand, three models

Revosolution robotic cells are available in three different models to suit different needs. There’s the Rapido, the Dinamico and the Robusto. The main differences between these three models are in terms of weight and dimensions.

All three models are easily adaptable to Ermaksan press brakes, also available in our catalog.

We invite you to find out more in the Robot Cells section of our online catalog.

The benefits of robotization

In all three models, the cell relies on technology from robotic brand Nachi. These robots have the capacity to operate continuously. This means they can deliver 24/7 performance.

The robotic cells used for sheet metal bending bring a number of advantages to manufacturing processes. First and foremost, they offer exceptional precision. Thanks to meticulous programming, the robots execute movements with minimal tolerance. This ensures that every operation precisely meets technical specifications.

Secondly, the repeatability of Nachi robots is a major asset. Once a program has been defined, it can repeat exactly the same movement. This feature reduces the variations that can occur with human operators.

What’s more, the robots ensure consistency in the bending process. Each part is bent identically, an essential aspect for mass production where uniformity is crucial.

Time optimization is a key benefit of robotic cells. They are fast and efficient. They can bend parts quickly. This increases productivity and reduces lead times.

Benefits for industrial production

More broadly speaking, deciding to make the switch to robotization in your plant brings its own set of benefits.

At the same time, robotization improves safety in the workplace. By automating repetitive, dangerous or physically demanding tasks, the risk of accidents for workers is reduced. This makes the workplace safer, and allows employees to concentrate on more important tasks, such as innovation or problem-solving.

Finally, investing in automation is a strategic decision to strengthen a company’s long-term sustainability. By reducing labor costs, improving resource efficiency and increasing production capacity, companies can better position themselves in the face of global competition and anticipate future needs.

We can always justify cost savings as another benefit. Technologies are backed up by regular maintenance and timely monitoring, helping to avoid unexpected breakdowns and their consequences. The smooth operation of technologies naturally reduces the number of errors and accidents in the workplace.

Full service with BV Machinery

We’re proud to always offer you a solid experience with us. We’d like to remind you how your company can benefit from turnkey service with BV Machinery.

First, we assemble the robotic cell with the press brake directly in our warehouse. Our team ensures that your machine tools meet industry standards.

We also offer a training service to ensure that your new purchase can be operated efficiently. Sharing knowledge is essential to us. We then install directly in your production environment.

When you do business with BV Machinery, you can rest assured that you’ll be supported every step of the way.

It’s time to live the BV Experience!

Back to articles