Tecoi – A brand with a wide range of products

[MBL series] – Laser cutting in the smallest spaces

TECOI’s cutting table with automatic pallet changer (CAP) is a mid-sized machine that optimizes production line productivity, handling a high volume of orders while reducing operating costs compared to traditional systems.

Its compact, robust design minimizes footprint and guarantees durability for demanding jobs.

[FL Series] – Cutting through flexibility and robustness

FL Series models are the ideal solution for tube and profile cutting processes using plasma, oxygas and solid laser, with a machine area available for flat cutting or even beveling work.

The ability to automate and perform a variety of processes in a very compact machine makes these models among the most cost-effective on the market.

[LS Series] – Laser cutting of large dimensions

The LS SERIES range of machines is specially designed for fiber and semiconductor laser cutting of medium and large formats and thicknesses.

TECOI has developed exclusive and innovative technologies, such as the DFP® automatic fiber changing system and the TWIN DISK double-head cutting system, enabling customers to achieve high production capacity and maximum flexibility for a variety of jobs.

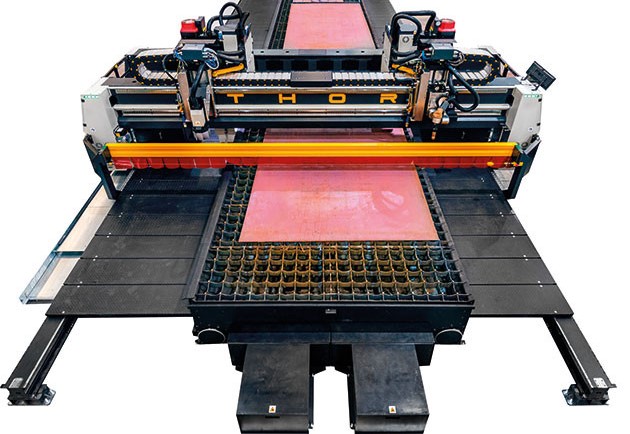

[THOR] – Versatility has a name

Thor is one of the most versatile sheet metal processing stations on the market. Maximum design and robustness for exceptional productivity.

[TRC] – Increased precision and machining performance

The TRC series is designed for high-intensity machining. When precision and repeatability are required, the TRC cutting series is ideal.

[TEKNOS] – Complementary processes for large dimensions

Robust and versatile, TEKNOS machines offer high work capacity and a variety of cutting options (plasma, beveling, oxy-fuel, drilling, marking, tube cutting), guaranteeing precision and reliability for demanding large-scale cutting.

Large formats and thicknesses + Multifunction combined plasma, oxycutting and machining