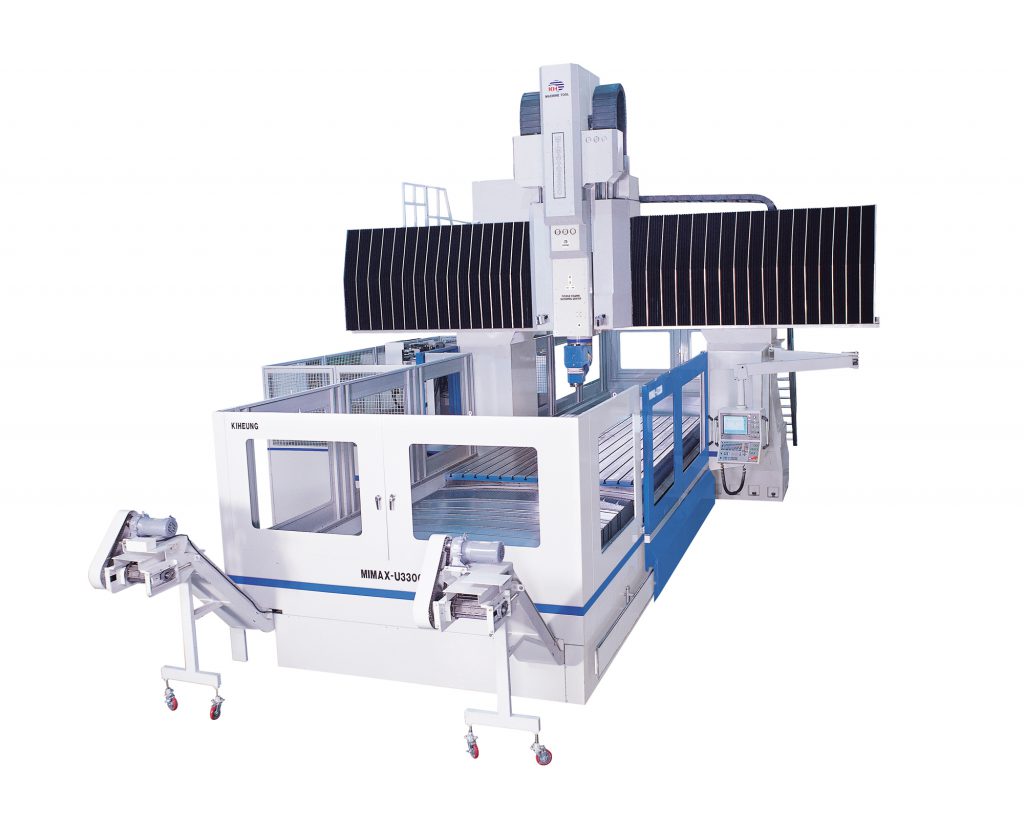

The MiMAX series is a high-performance bridge machining center with a universal head. It offers 42 kW of power and 1638 Nm of torque. For intensive work or high-speed machining, several spindle types (geared, belt-driven and direct) are available.

Automatic positioning with a 2-axis head enables 5-sided machining. Weighing 115 tonnes, the machine can handle workpieces weighing up to 30 tonnes. INA LM linear guides on the X and Y axes ensure high precision, rapid movements and low abrasion. The Z axis, equipped with a highly rigid guide, is suitable for heavy cutting conditions and can be fitted with linear roller guides for high spindle speeds.

- Controller: HEIDENHAIN iTNC 640, SIEMENS 840D, FANUC 31i

- Table dimensions: 1800~3500 x 3500~10000mm

- X axis: 3700~10300mm

- Y axis: 3000~5500mm

- Z axis: 800~1600mm

- Feed: 10000mm

- Rapid: 20000mm

- Spindle power: 22/33, 28/42kW

COLUMN CLEARANCE (mm): 2300~4500

TABLE:

Length & Width (mm): 1800~3500×3500~10000

TRAVEL:

Longitudinal (mm): 4000~10500

Cross (mm): 3000~5500

Vertical (mm): 800/1000/1200/1600/2000

FEED:

Axis (mm/min): 10000

Rapid (mm/min): 20000(X,Y,Z)

SPINDLE:

Motor (kW): 22/33, 28/42

Speed (rpm): 3000 (2 step : 0~1125, 1126~3000) Programmable universal head available 2,5° x 2,5° to 0,001 x 0,001

WEIGHT (kg): 45000~90000