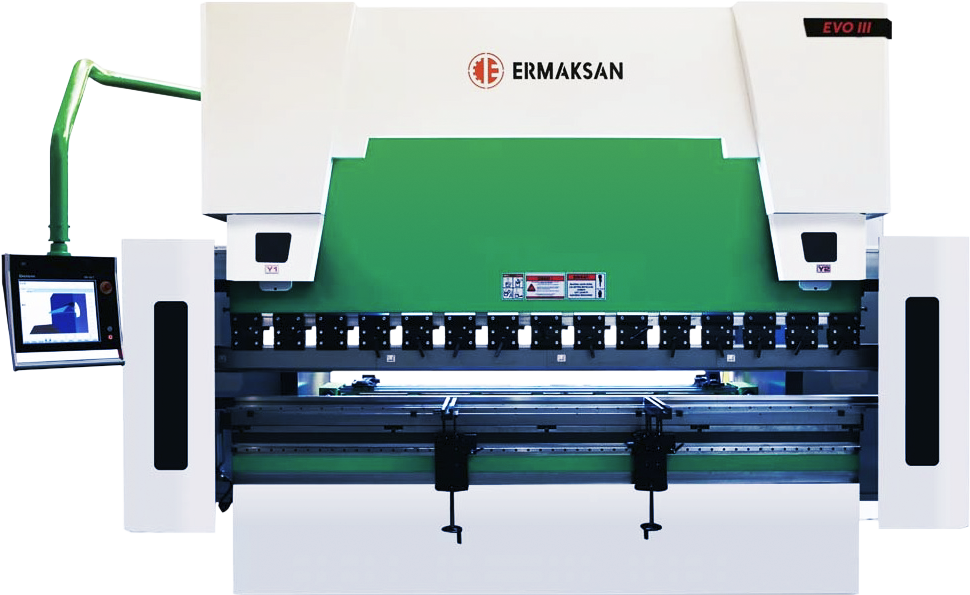

The EVO III hybrid press brake, a 6-axis CNC machine, excels in precision bending with silent operation and very low energy consumption. It combines ergonomics, aesthetics and functionality, offering a unique and environmentally-friendly user experience.

High productivity is ensured by a fast Y-axis speed of 200 mm/s, for rapid tool positioning, and a working speed of 10 mm/s for precise bending. The return speed of 190 mm/s reduces non-productive time.

The servomotor, which activates the motor only when the cylinder is in motion, delivers energy savings of 73% compared with a conventional 110-ton CNC hydraulic press brake. The closed-loop hydraulic system requires less maintenance, consumes little energy, with an average oil consumption of 34.5 liters, and maintains a low noise level of 63 dB, making it extremely quiet.

Hybrid Press Brake

Standard Equipments:

6 Axis backgauge (Y1, Y2, X, R, Z1, Z2)

Delem controller

CNC motorized crowning

Options:

Sheet follower systems

Clamping systems

Wila systems

Interested in this product?

Contact us for a quote or more information.

Need advice?

Need advice?